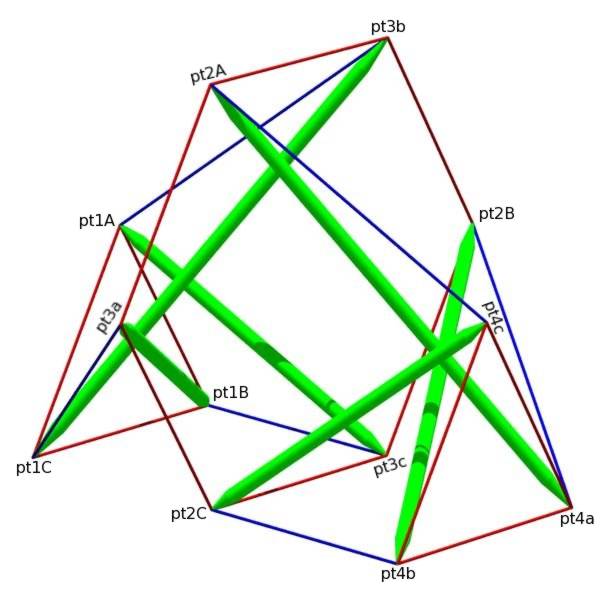

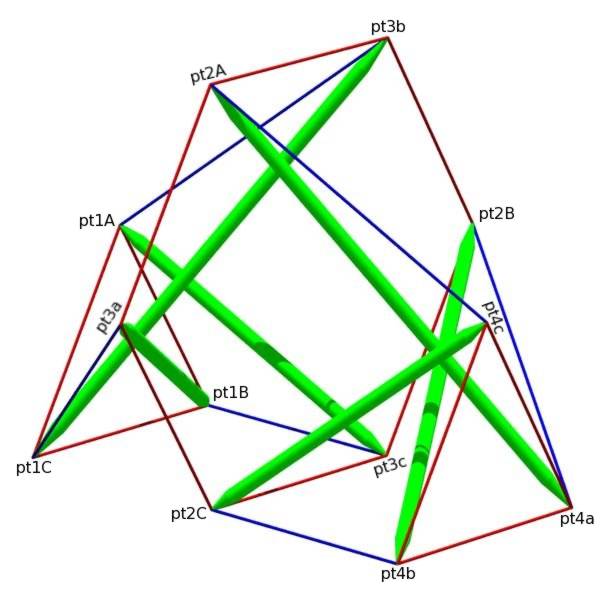

Structure Based on Laminated Skew Prisms with Point Labels

structure file: mast/x3l2mast2b.rc

variable file: mast/x3l2mast2b.dat

digit list: src/mm.dls

|

Member Descriptions

[name, end point names, weight (if in objective function),

second power of length (if a constraint), member category,

Obj/Con/Exc (put in objective function, use as a constraint or

exclude from computations), flags]

For assembly purposes, only the name and end point names are

of interest. The other information may be of interest after

A Practical Guide to Tensegrity Design has been consulted.

<Member> strut13a pt1A pt3c -1.0 2.0 1 Con *

<Member> strut24a pt2A pt4a -1.0 5.0 1 Con *

<Member> end1a pt1A pt1B 1.0 sqr(1.0) 2 Con *

<Member> end2a pt4a pt4b 1.0 sqr(1.0) 2 Con *

<Member> guy1a pt1A pt3b 1.0 sqr(1.0) 3 Obj *

<Member> guy2a pt2C pt4b 1.0 sqr(1.0) 3 Obj *

<Member> eq1a pt2A pt3a 1.0 sqr(1.0) 2 Con *

<Member> eq2a pt2A pt3b 1.0 sqr(1.0) 2 Con *

<Member> strut13b pt1B pt3a -1.0 4.0 1 Con *

<Member> strut24b pt2B pt4b -1.0 4.0 1 Con *

<Member> end1b pt1B pt1C 1.0 sqr(1.0) 2 Con *

<Member> end2b pt4b pt4c 1.0 sqr(1.0) 2 Con *

<Member> guy1b pt1B pt3c 1.0 sqr(1.0) 3 Obj *

<Member> guy2b pt2A pt4c 1.0 sqr(1.0) 3 Obj *

<Member> eq1b pt2B pt3b 1.0 sqr(1.0) 2 Con *

<Member> eq2b pt2B pt3c 1.0 sqr(1.0) 2 Con *

<Member> strut13c pt1C pt3b -1.0 5.0 1 Con *

<Member> strut24c pt2C pt4c -1.0 2.0 1 Con *

<Member> end1c pt1C pt1A 1.0 sqr(1.0) 2 Con *

<Member> end2c pt4c pt4a 1.0 sqr(1.0) 2 Con *

<Member> guy1c pt1C pt3a 1.0 sqr(1.0) 3 Obj *

<Member> guy2c pt2B pt4a 1.0 sqr(1.0) 3 Obj *

<Member> eq1c pt2C pt3c 1.0 sqr(1.0) 2 Con *

<Member> eq2c pt2C pt3a 1.0 sqr(1.0) 2 Con *

In-Situ Member Lengths

These are the lengths of the members when they are in place

and prestress is applied. The strut lengths are from pin insertion

point to pin insertion point, as are the tendon lengths.

The values are in model units.

strut13a: 1.41421 strut24a: 2.23607 end1a: 1

end2a: 1 guy1a: 1.41421 guy2a: 1

eq1a: 1 eq2a: 1 strut13b: 2

strut24b: 2 end1b: 1 end2b: 1

guy1b: 1 guy2b: 1.41421 eq1b: 1

eq2b: 1 strut13c: 2.23607 strut24c: 1.41421

end1c: 1 end2c: 1 guy1c: 1.41421

guy2c: 1.41421 eq1c: 1 eq2c: 1

Relative Member Force Magnitudes

These values are useful for developing an assembly

strategy for the structure. The tighter tendons are much

easier to tie in place early on, while the looser tendons

can be left to the last. This information is also used

to adjust tendon lengths since the measured length of a tendon

will be shorter for a highly-stressed tendon with the same

in-situ length as a tendon which is not so stressed.

strut13a: -1.41421 strut24a: -2.23607 end1a: 1

end2a: 1 guy1a: 1.41421 guy2a: 1

eq1a: 1 eq2a: 1 strut13b: -2

strut24b: -2 end1b: 1 end2b: 1

guy1b: 1 guy2b: 1.41421 eq1b: 1

eq2b: 1 strut13c: -2.23607 strut24c: -1.41421

end1c: 1 end2c: 1 guy1c: 1.41421

guy2c: 1.41421 eq1c: 1 eq2c: 1

Average tendon force magnitude: 1.09205

Construction Lengths (in millimeters and halves)

The construction length of a tendon is less than the in-situ

length since when the tendon is measured off it isn't under

any prestress force. The construction length for the strut

represents the length of the 3/16-inch-diameter wooden dowel.

The tendons were made of 12-lb.-test braided nylon fishing line.

In this case, the attachment point at the hubs was a simple

metal pin stuck into the end of the strut, so no member-length

adjustments were necessary. Prestress forces are assumed

not to affect strut lengths.

Elongation of Tendon of Unit Cross Section

Under Force of Average Magnitude (fraction)> .02

Length Scale Factor> 88/sqrt(2)

Strut and Tendon Hub Adjustments - s;t> 0 0

strut13a: 88 0 strut24a: 139 0 end1a: 61 0 end2a: 61 0

guy1a: 86 0 guy2a: 61 0 eq1a: 61 0 eq2a: 61 0

strut13b: 124 1 strut24b: 124 1 end1b: 61 0 end2b: 61 0

guy1b: 61 0 guy2b: 86 0 eq1b: 61 0 eq2b: 61 0

strut13c: 139 0 strut24c: 88 0 end1c: 61 0 end2c: 61 0

guy1c: 86 0 guy2c: 86 0 eq1c: 61 0 eq2c: 61 0

Material Quantities (in millimeters)

Estimates of the total amount of material required to build

the structure. The adjustment in this case includes "waste":

for the strut, the amount lost when sawing the strut from a

length of dowel (1 mm from each end); for the tendons, the amount

of extra needed to successfully tie the tendon (50 mm extra at

each end).

Elongation of Tendon of Unit Cross Section

Under Force of Average Magnitude (fraction)> .02

Length Scale Factor> 88/sqrt(2)

Strut and Tendon Adjustments - s;t> -1, -50

Cross

Type Section Quantity Count

1 1 715.182 6

2 1 1911.69 12

3 1 1051.63 6

Strts 715.182 6

Tndns 2963.32 18

Structure Based on Laminated Skew Prisms with Point Labels

structure file: mast/x3l2mast2b.rc

variable file: mast/x3l2mast2b.dat

digit list: src/mm.dls

|

|

CONTACT: Bob Burkhardt Tensegrity Solutions Box 426164 Cambridge, MA 02142-0021 USA e-mail: bobwb@juno.com |

Back to

Structure Based on Laminated Skew Prisms

More Datasheets