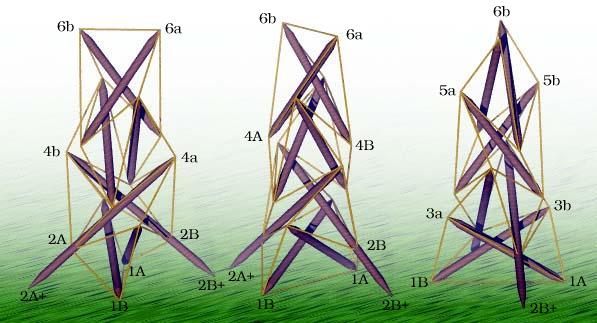

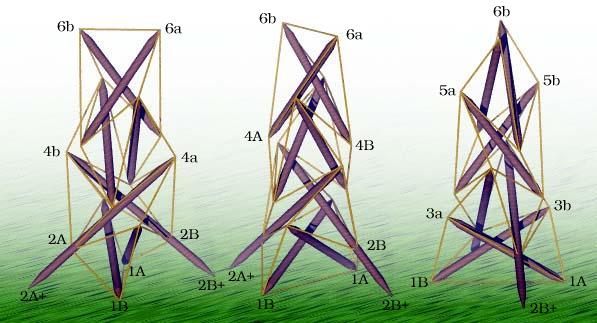

Three Views of the Bean Teepee

structure file: chain/x2l4chain1a.rc variable file: chain/x2l4chain1a.dat stress-strain chart file: v02oct_s/evans.ssc cross-section table: chain/x2l4chain1a.cst digit list file: src/standard.dls |

Member Descriptions

[name, end point names, weight (if in objective function),

second power of length (if a constraint), member category,

Obj/Con/Exc (put in objective function, use as a constraint or

exclude from computations), flags]

For assembly purposes, only the name and end point names are

of interest. The other information may be of interest after

A Practical Guide to Tensegrity Design has been consulted.

first stage

<Member> end1 p1A p1B 0.0 sqr(1.3*1.24030) 4 Con *

<Member> st13 p1A p3a 0.0 sqr(1.685867) 1 Con CalcClear Inelastic *

<Member> side1a p1A p3b 1.0 0.0 3 Obj *

<Member> side1c p1A p2B 1.0 0.0 3 Obj *

<Member> gird1a p2A p3a 0.0 sqr(1.0) 2 Con *

<Member> gird1b p2A p3b 0.0 sqr(1.0) 2 Con *

second (complete) stage

<Member> st24 p2A+ p4a 0.0 sqr(1.685867*1.4146184) 1 Con CalcClear Inelastic *

<Member> side2a p2A p4b 1.0 0.0 3 Obj *

<Member> side2b p4a p3a 1.0 0.0 3 Obj *

<Member> side2c p2A p3B 1.0 0.0 3 Obj *

<Member> gird2a p4a p3B 0.0 sqr(1.0) 2 Con *

<Member> gird2b p4a p3A 0.0 sqr(1.0) 2 Con *

third (complete) stage

<Member> st35 p3A p5a 0.0 sqr(1.685867) 1 Con CalcClear Inelastic *

<Member> side3a p3A p5b 1.0 0.0 3 Obj *

<Member> side3b p5a p4a 1.0 0.0 3 Obj *

<Member> side3c p3A p4B 1.0 0.0 3 Obj *

<Member> gird3a p5a p4B 0.0 sqr(1.0) 2 Con *

<Member> gird3b p5a p4A 0.0 sqr(1.0) 2 Con *

fourth and last stage

<Member> st46 p4A p6a 0.0 sqr(1.685867) 1 Con CalcClear Inelastic *

<Member> side4a p4A p6b 1.0 0.0 3 Obj *

<Member> side4b p6a p5a 1.5 0.0 3 Obj *

<Member> end2 p6b p6a 0.0 sqr(1.24030/1.3) 4 Con *

In-Situ Member Lengths

These are the lengths of the members when they are in place

and prestress is applied. The strut lengths are from

screw-eye center to screw-eye center, as are the tendon lengths.

These values are in model units.

end1: 1.61239 st13: 1.68587 side1a: 0.923189

side1c: 0.953076 gird1a: 1 gird1b: 1

st24: 2.38486 side2a: 1.17827 side2b: 0.97929

side2c: 0.846298 gird2a: 1 gird2b: 1

st35: 1.68587 side3a: 1.38778 side3b: 0.998633

side3c: 0.832481 gird3a: 1 gird3b: 1

st46: 1.68587 side4a: 1.40257 side4b: 0.874856

end2: 0.954077

Relative Member Prestress Force Magnitudes

These values are useful for developing an assembly

strategy for the structure. The tighter tendons are much

easier to tie in place early on, while the looser tendons

can be left to the last. This information is also used

to adjust tendon lengths since the measured length of a tendon

will be shorter for a highly-stressed tendon with the same

in-situ length as a tendon which is not so stressed.

Since the symmetry transform maps end1 and end2 into

themselves, they each represent two overlapping tendons,

each with the force magnitude given below. So, the total

force is actually twice the value given for end1 and end2.

end1: 0.707352 st13: -2.58943 side1a: 0.923189

side1c: 0.953076 gird1a: 1.35245 gird1b: 1.58822

st24: -2.59752 side2a: 1.17827 side2b: 0.97929

side2c: 0.846298 gird2a: 1.39285 gird2b: 1.3656

st35: -3.56761 side3a: 1.38778 side3b: 0.998633

side3c: 0.832481 gird3a: 1.10818 gird3b: 1.4817

st46: -2.98368 side4a: 1.40257 side4b: 1.31228

end2: 0.649404

Average tendon force magnitude: 1.13665

Construction Lengths (in inches, 16ths and 32nds)

The construction length of a tendon is less than the in-situ

length since when the tendon is measured off it isn't under

any prestress force. The construction length for a member

represents the distance between the locations where it

departs from the hub. The struts were cut from

1-inch by 1-inch hardwood garden stakes. The lengths below

are specified for braided nylon twine (e.g. T.W. Evans

#1 Braided Nylon Mason Line -- Item No. 12-503). Its behavior

under stress is highly non-linear, so a look-up table

was used to compute strains. It seems to be slightly more

stretchy than twine composed of twisted strands

(e.g. Wellington #18 Nylon Twine -- Prod. No. 46302).

Prestress forces were assumed to affect tendon lengths and

not strut lengths.

Average Tendon Force Magnitude (chart units)> 20

Length Scale Factor> 34/1.685867

Strut and Tendon Hub Adjustments> 0 0.5

(adjust the tendon lengths by subtracting a half inch from

both ends)

end1: 27 11 1 st13: 34 0 0 side1a: 15 15 0 side1c: 16 7 0

gird1a: 16 14 1 gird1b: 16 11 0 st24: 48 1 1 side2a: 20 5 0

side2b: 16 14 0 side2c: 14 10 0 gird2a: 16 14 0 gird2b: 16 14 1

st35: 34 0 0 side3a: 23 12 1 side3b: 17 3 1 side3c: 14 6 0

gird3a: 17 2 1 gird3b: 16 12 1 st46: 34 0 0 side4a: 24 0 0

side4b: 14 11 1 end2: 16 2 1

Material Quantities

This provides an estimate of how much material will

be needed to assemble the structure, in this case

inches of garden stake and inches of nylon twine.

The lengths must be adjusted to take into account the

fact that the strut extends past the hub and some length

of tendon is required to tie it to the strut.

These values don't take into account that two struts

have a significant extention to provide for the stability

of the structure when used as a tower.

Length Scale Factor> 34/1.685867

Strut and Tendon Adjustments> (-1) (-6)

(adjust the strut lengths by adding an inch to

both ends; adjust the tendon lengths by adding

six inches to both ends)

Cross

Type Section Quantity Count

4 0.5 133.629 4

1 1 316.194 8

3 1 589.668 20

2 1 340.121 12

Strts 316.194 8

Tndns 996.603 36

Three Views of the Bean Teepee

structure file: chain/x2l4chain1a.rc variable file: chain/x2l4chain1a.dat stress-strain chart file: v02oct_s/evans.ssc cross-section table: chain/x2l4chain1a.cst digit list file: src/standard.dls |

CONTACT:

Bob Burkhardt

Tensegrity Solutions

Box 426164

Cambridge, MA 02142-0021

USA

e-mail: bobwb@juno.com