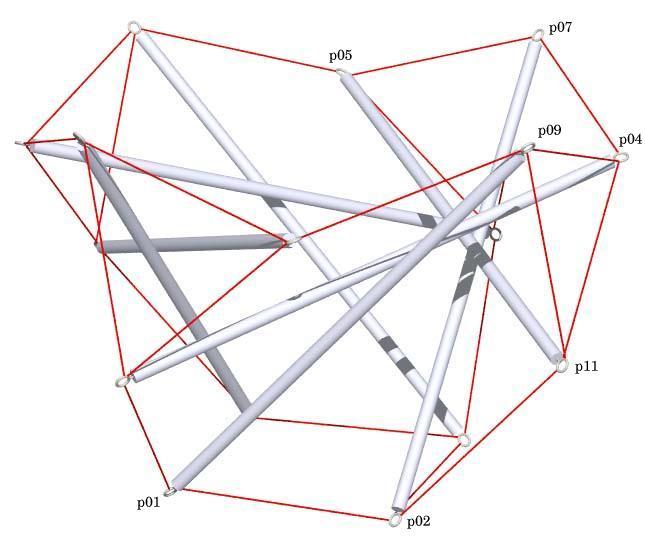

View of the Tensegrity Tulip

with Point Labels

Hub Connectivity

This shows how hub vectors (hv01.1 ...) are applied to the

strut end points (p01 ...) to derive hub points (hp01.1 ...).

Hub points are where tendons are connected to the strut.

<VecPt> hp01.1 p01 + hv01.1

<VecPt> hp01.2 p01 + hv01.2

<VecPt> hp01.3 p01 + hv01.3

<VecPt> hp05.1 p05 + hv05.1

<VecPt> hp05.2 p05 + hv05.2

<VecPt> hp05.3 p05 + hv05.3

<VecPt> hp09.1 p09 + hv09.1

<VecPt> hp09.2 p09 + hv09.2

<VecPt> hp09.3 p09 + hv09.3

<VecPt> hp11.1 p11 + hv11.1

<VecPt> hp11.2 p11 + hv11.2

<VecPt> hp11.3 p11 + hv11.3

Transformations

This shows how transforms are defined and how they are

applied to derive transformed objects from basic objects.

# rotation matrices

<XMat> x4 cos(2*pi/4) (-sin(2*pi/4)) 0 sin(2*pi/4) cos(2*pi/4) 0 0 0 1

<CompositeXform> x4^2 x4 x4

<CompositeXform> x4^3 x4 x4^2

# transform points and vectors

<XformPt> p02 p01 x4

<XformPt> hp02.1 hp01.1 x4

<XformPt> hp02.2 hp01.2 x4

<XformPt> hp02.3 hp01.3 x4

<XformPt> p04 p05 x4^3

<XformPt> hp04.1 hp05.1 x4^3

<XformPt> hp04.2 hp05.2 x4^3

<XformPt> hp04.3 hp05.3 x4^3

<XformPt> p07 p09 x4

<XformPt> hp07.1 hp09.1 x4

<XformPt> hp07.2 hp09.2 x4

<XformPt> hp07.3 hp09.3 x4

Member Descriptions

[name, end point names, weight (if in objective function),

second power of length (if a constraint), member category,

Obj/Con/Exc (put in objective function, use as a constraint or

exclude from computations), flags]

For assembly purposes, only the name and end point names are

of interest. The other information may be of interest after

A Practical Guide to Tensegrity Design has been consulted.

# struts

<Member> strut1 p01 p09 0.00 sqr(317) 1 Con CalcClear *

<Member> strut2 p05 p11 0.00 sqr(317) 1 Con CalcClear *

# square tendon

<Member> sqten hp01.1 hp02.2 0.00 sqr(129.2792) 2 Con *

# triangle tendons

<Member> triten1 hp04.1 hp09.1 0.00 sqr(129.2792) 2 Con *

<Member> triten2 hp09.2 hp11.1 0.00 sqr(129.2792) 2 Con *

<Member> triten3 hp11.2 hp04.2 0.00 sqr(129.2792) 2 Con *

# zig-zag tendons

<Member> zzten1 hp02.3 hp11.3 1.00 0.00 3 Obj *

<Member> zzten2 hp04.3 hp07.3 1.00 sqr(129.2792) 3 Con *

Hub Constructs

These items are just vectors corresponding to each of the

struts. At some point the software will be modified so

these items aren't necessary since it should be possible

to treat any member as a vector without explicit constructs.

<DiffVec> strut1v p01 p09

<DiffVec> strut2v p05 p11

Hub Constraints

These are constraints the hub vectors must meet. For

these constraints to be specified, a set of

center vectors (cv01, ...) is introduced. There is one

center vector for each strut end point. The center vectors

are constrained to be orthogonal to the strut. For each

tendon connected to a strut end point, there is a hub

vector. All the hub vectors at a strut end point must

be orthogonal to the corresponding center vector and

4 mm long. 4 mm is the outer radius of the screw eye.

The center vectors are constrained to be of length one

just to make their values well defined.

<VecDotVec> hubdot01 strut1v cv01 1.0 0.0 Con

<VecLength> cvlen01 cv01 1.0 sqr(1.0) Con

<VecDotVec> hubdot01.1 cv01 hv01.1 1.0 0.0 Con

<VecDotVec> hubdot01.2 cv01 hv01.2 1.0 0.0 Con

<VecDotVec> hubdot01.3 cv01 hv01.3 1.0 0.0 Con

<VecLength> hvlen01.1 hv01.1 1.0 sqr(4.0) Con

<VecLength> hvlen01.2 hv01.2 1.0 sqr(4.0) Con

<VecLength> hvlen01.3 hv01.3 1.0 sqr(4.0) Con

<VecDotVec> hubdot09 strut1v cv09 1.0 0.0 Con

<VecLength> cvlen09 cv09 1.0 sqr(1.0) Con

<VecDotVec> hubdot09.1 cv09 hv09.1 1.0 0.0 Con

<VecDotVec> hubdot09.2 cv09 hv09.2 1.0 0.0 Con

<VecDotVec> hubdot09.3 cv09 hv09.3 1.0 0.0 Con

<VecLength> hvlen09.1 hv09.1 1.0 sqr(4.0) Con

<VecLength> hvlen09.2 hv09.2 1.0 sqr(4.0) Con

<VecLength> hvlen09.3 hv09.3 1.0 sqr(4.0) Con

<VecDotVec> hubdot05 strut2v cv05 1.0 0.0 Con

<VecLength> cvlen05 cv05 1.0 sqr(1.0) Con

<VecDotVec> hubdot05.1 cv05 hv05.1 1.0 0.0 Con

<VecDotVec> hubdot05.2 cv05 hv05.2 1.0 0.0 Con

<VecDotVec> hubdot05.3 cv05 hv05.3 1.0 0.0 Con

<VecLength> hvlen05.1 hv05.1 1.0 sqr(4.0) Con

<VecLength> hvlen05.2 hv05.2 1.0 sqr(4.0) Con

<VecLength> hvlen05.3 hv05.3 1.0 sqr(4.0) Con

<VecDotVec> hubdot11 strut2v cv11 1.0 0.0 Con

<VecLength> cvlen11 cv11 1.0 sqr(1.0) Con

<VecDotVec> hubdot11.1 cv11 hv11.1 1.0 0.0 Con

<VecDotVec> hubdot11.2 cv11 hv11.2 1.0 0.0 Con

<VecDotVec> hubdot11.3 cv11 hv11.3 1.0 0.0 Con

<VecLength> hvlen11.1 hv11.1 1.0 sqr(4.0) Con

<VecLength> hvlen11.2 hv11.2 1.0 sqr(4.0) Con

<VecLength> hvlen11.3 hv11.3 1.0 sqr(4.0) Con

In-Situ Member Lengths

These are the lengths of the members when they are in place

and prestress is applied. The strut lengths are from

screw-eye center to screw-eye center. The tendon lengths

are from screw-eye rim to screw-eye rim. Since the model

has been scaled appropriately, these values are in millimeters.

strut1: 317 strut2: 317 sqten: 129.279

triten1: 129.279 triten2: 129.279 triten3: 129.279

zzten1: 129.279 zzten2: 129.279

Relative Member Prestress Force Magnitudes

These values are useful for developing an assembly

strategy for the structure. The tighter tendons are much

easier to tie in place early on, while the looser tendons

can be left to the last. This information is also used

to adjust tendon lengths since the measured length of a tendon

will be shorter for a highly-stressed tendon with the same

in-situ length as a tendon which is not so stressed.

strut1: -129.702 strut2: -133.842 sqten: 79.7366

triten1: 83.7261 triten2: 32.1339 triten3: 150.757

zzten1: 129.279 zzten2: 135.186

Construction Lengths (in millimeters and halves)

The construction length of a tendon is less than the in-situ

length since when the tendon is measured off it isn't under

any prestress force. The construction length for the strut

represents the length of the wooden dowel. Prestress forces

are assumed to affect tendon lengths and not strut lengths.

Here no ad hoc adjustment is necessary for the tendons since

the hubs are included explicitly in the mathematical

programming problem.

Elongation of Tendon of Unit Cross Section

Under Force of Average Magnitude (fraction)> 0.02

Length Scale Factor> 1.0

(Things are scaled so model and construction units are the same.)

Strut and Tendon Hub Adjustments - s;t> 6.5 0

(Hub connections were handled explicity in the mathematical

programming problem, so no ad hoc adjustment is needed here

to account for the tendon hub connections. The 6.5 mm

adjustment for the strut represents the amount the

screw-eye center extends from the dowel.)

strut1: 304 0 strut2: 304 0 sqten: 127 1

triten1: 127 0 triten2: 128 1 triten3: 125 1

zzten1: 126 0 zzten2: 126 0

Construction Lengths -- ad hoc adjustment

For comparison, these are the construction lengths computed

from the model where all members are assumed to meet

at a single point and a simple ad hoc adjument is applied

to account for hub geometry. If the the ad hoc adjustment

is working well, the values here should be the same as the

ones above. All the tendon values are 0.5 mm off, which is

within assembly tolerances. This is good, because it means

the ad hoc adjustment works. It is much easier to do the

ad hoc adjustment than to model the hubs explicitly.

Elongation of Tendon of Unit Cross Section

Under Force of Average Magnitude (fraction)> .02

Length Scale Factor> 317/2.31755

Strut and Tendon Hub Adjustments - s;t> 6.5 4.0

(The 6.5 mm adjustment for the strut is the amount

the screw-eye center extends from the dowel. The 4 mm

adjustment for the tendon is half the outer diameter of the

screw eye.)

strut1: 304 0 strut2: 304 0 sqten: 127 0

triten1: 126 1 triten2: 128 0 triten3: 125 0

zzten1: 125 1 zzten2: 125 1

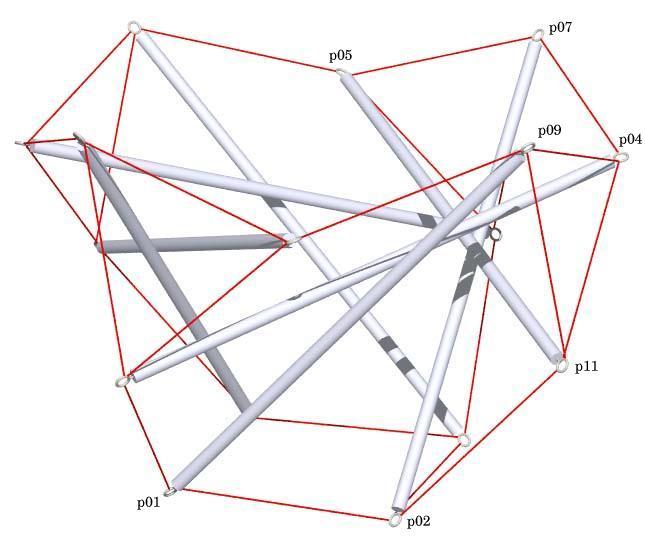

View of the Tensegrity Tulip

with Point Labels

structure files: flower/x4flower1.rc (ad hoc)

flower/x4flower1c.rc (exact)

variable files: flower/x4flower1.dat

flower/x4flower1c.dat

digit list: src/mm.dls

|

CONTACT:

Bob Burkhardt

Tensegrity Solutions

Box 426164

Cambridge, MA 02142-0021

USA

e-mail: bobwb@juno.com