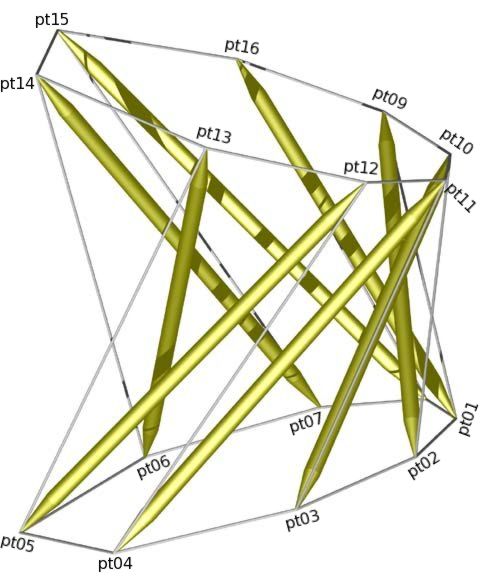

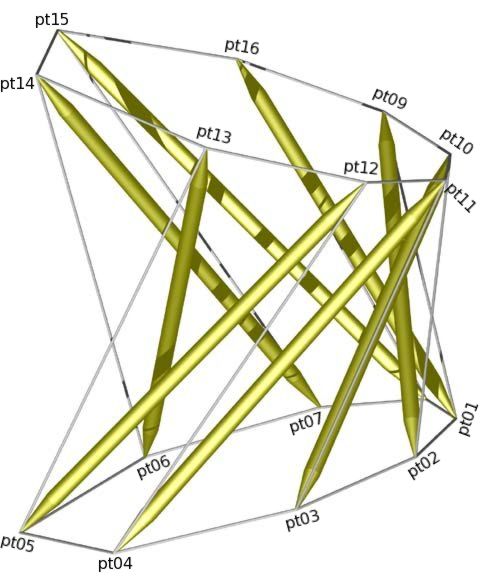

Perspective Prism with Point Labels

structure file: sk8prsm/stage6.rc

variable file: sk8prsm/stage6.dat

digit list: src/mm.dls

|

Member Descriptions

[name, end point names, weight (if in objective function),

second power of length (if a constraint), member category,

Obj/Con/Exc (put in objective function, use as a constraint or

exclude from computations), flags]

For assembly purposes, only the name and end point names are

of interest. The other information may be of interest after

A Practical Guide to Tensegrity Design has been consulted.

<Member> 01(c) pt01 pt02 0.0 sqr(0.261008730199888) 2 Con *

<Member> 02(c) pt02 pt03 0.0 sqr(0.301915332950701) 2 Con *

<Member> 03(c) pt03 pt04 0.0 sqr(0.383095246542990) 2 Con *

<Member> 04(c) pt04 pt05 0.0 sqr(0.464146377838545) 2 Con *

<Member> 05(c) pt05 pt06 0.0 sqr(0.464146377838546) 2 Con *

<Member> 06(c) pt06 pt07 0.0 sqr(0.383095246542990) 2 Con *

<Member> 07(c) pt07 pt08 0.0 sqr(0.301915332950701) 2 Con *

<Member> 08(c) pt08 pt01 0.0 sqr(0.261008730199888) 2 Con *

<Member> 09(c) pt01 pt09 1.0 sqr(0.689891161160713) 3 Obj *

<Member> 10(c) pt02 pt10 1.0 sqr(0.665510875807512) 3 Con *

<Member> 11(c) pt03 pt11 1.0 sqr(0.739256300739300) 3 Con *

<Member> 12(c) pt04 pt12 1.0 sqr(0.908039523981026) 3 Con *

<Member> 13(c) pt05 pt13 1.0 sqr(1.09882495341673) 3 Con *

<Member> 14(c) pt06 pt14 1.0 sqr(1.14981051589702) 3 Con *

<Member> 15(c) pt07 pt15 1.0 sqr(1.01049024008915) 3 Con *

<Member> 16(c) pt08 pt16 1.0 sqr(0.813398015083213) 3 Con *

<Member> 17(s) pt01 pt16 -1.0 sqr(0.930211225870888) 1 Con *

<Member> 18(s) pt02 pt09 -1.0 sqr(0.849854394375223) 1 Con *

<Member> 19(s) pt03 pt10 -1.0 sqr(0.877233805489365) 1 Con *

<Member> 20(s) pt04 pt11 -1.0 sqr(1.00302205041128) 1 Con *

<Member> 21(s) pt05 pt12 -1.0 sqr(1.15285087051696) 1 Con *

<Member> 22(s) pt06 pt13 -1.0 sqr(1.21931486941198) 1 Con *

<Member> 23(s) pt07 pt14 -1.0 sqr(1.19871926268034) 1 Con *

<Member> 24(s) pt08 pt15 -1.0 sqr(1.08313829018149) 1 Con *

<Member> 25(c) pt09 pt10 0.0 sqr(0.276112253335532) 2 Con *

<Member> 26(c) pt10 pt11 0.0 sqr(0.256060301692048) 2 Con *

<Member> 27(c) pt11 pt12 0.0 sqr(0.276112253335532) 2 Con *

<Member> 28(c) pt12 pt13 0.0 sqr(0.338385830283023) 2 Con *

<Member> 29(c) pt13 pt14 0.0 sqr(0.428933030260907) 2 Con *

<Member> 30(c) pt14 pt15 0.0 sqr(0.477402187936063) 2 Con *

<Member> 31(c) pt15 pt16 0.0 sqr(0.428933030260908) 2 Con *

<Member> 32(c) pt16 pt09 0.0 sqr(0.338385830283022) 2 Con *

In-Situ Member Lengths

These are the lengths of the members when they are in place

and prestress is applied. The strut lengths are from pin insertion

point to pin insertion point, as are the tendon lengths.

The values are in model units.

01(c): 0.261009 02(c): 0.301915 03(c): 0.383095

04(c): 0.464146 05(c): 0.464146 06(c): 0.383095

07(c): 0.301915 08(c): 0.261009 09(c): 0.689891

10(c): 0.665511 11(c): 0.739256 12(c): 0.90804

13(c): 1.09882 14(c): 1.14981 15(c): 1.01049

16(c): 0.813398 17(s): 0.930211 18(s): 0.849854

19(s): 0.877234 20(s): 1.00302 21(s): 1.15285

22(s): 1.21931 23(s): 1.19872 24(s): 1.08314

25(c): 0.276112 26(c): 0.25606 27(c): 0.276112

28(c): 0.338386 29(c): 0.428933 30(c): 0.477402

31(c): 0.428933 32(c): 0.338386

Relative Member Force Magnitudes

These values are useful for developing an assembly

strategy for the structure. The tighter tendons are much

easier to tie in place early on, while the looser tendons

can be left to the last. This information is also used

to adjust tendon lengths since the measured length of a tendon

will be shorter for a highly-stressed tendon with the same

in-situ length as a tendon which is not so stressed.

01(c): 0.373147 02(c): 0.325355 03(c): 0.257914

04(c): 0.210412 05(c): 0.210412 06(c): 0.257914

07(c): 0.325355 08(c): 0.373147 09(c): 0.689891

10(c): 0.714551 11(c): 0.644801 12(c): 0.526374

13(c): 0.433788 14(c): 0.413674 15(c): 0.472738

16(c): 0.58702 17(s): -0.723498 18(s): -0.788567

19(s): -0.765149 20(s): -0.672798 21(s): -0.585149

22(s): -0.549745 23(s): -0.560797 24(s): -0.623763

25(c): 0.353997 26(c): 0.379874 27(c): 0.353997

28(c): 0.291607 29(c): 0.229412 30(c): 0.20375

31(c): 0.229412 32(c): 0.291607

Average tendon force magnitude: 0.381256

Construction Lengths (in millimeters and halves)

The construction length of a tendon is less than the in-situ

length since when the tendon is measured off it isn't under

any prestress force. The construction length for the strut

represents the length of the 3/16-inch-diameter wooden dowel.

The tendons were made of 12-lb.-test braided nylon fishing line.

In this case, the attachment point at the hubs was a simple

metal pin stuck into the end of the strut, so no member-length

adjustments were necessary. Prestress forces are assumed

not to affect strut lengths.

Elongation of Tendon of Unit Cross Section

Under Force of Average Magnitude (fraction)> .02

Length Scale Factor> 125

Strut and Tendon Hub Adjustments - s;t> 0 0

01(c): 32 0 02(c): 37 0 03(c): 47 0 04(c): 57 1

05(c): 57 1 06(c): 47 0 07(c): 37 0 08(c): 32 0

09(c): 83 0 10(c): 80 0 11(c): 89 1 12(c): 110 1

13(c): 134 1 14(c): 140 1 15(c): 123 1 16(c): 98 1

17(s): 116 1 18(s): 106 0 19(s): 109 1 20(s): 125 1

21(s): 144 0 22(s): 152 1 23(s): 150 0 24(s): 135 1

25(c): 34 0 26(c): 31 1 27(c): 34 0 28(c): 41 1

29(c): 53 0 30(c): 59 0 31(c): 53 0 32(c): 41 1

Material Quantities (in millimeters)

Estimates of the total amount of material required to build

the structure. The adjustment in this case includes "waste":

for the strut, the amount lost when sawing the strut from a

length of dowel (1 mm from each end); for the tendons, the amount

of extra needed to successfully tie the tendon (20 mm extra at

each end).

Elongation of Tendon of Unit Cross Section

Under Force of Average Magnitude (fraction)> .02

Length Scale Factor> 125

Strut and Tendon Adjustments - s;t> -1 -20

Cross

Type Section Quantity Count

2 1 1325.31 16

3 1 1170.98 8

1 1 1055.29 8

Strts 1055.29 8

Tndns 2496.29 24

Perspective Prism with Point Labels

structure file: sk8prsm/stage6.rc

variable file: sk8prsm/stage6.dat

digit list: src/mm.dls

|

|

CONTACT: Bob Burkhardt Tensegrity Solutions Box 426164 Cambridge, MA 02142-0021 USA e-mail: bobwb@juno.com |