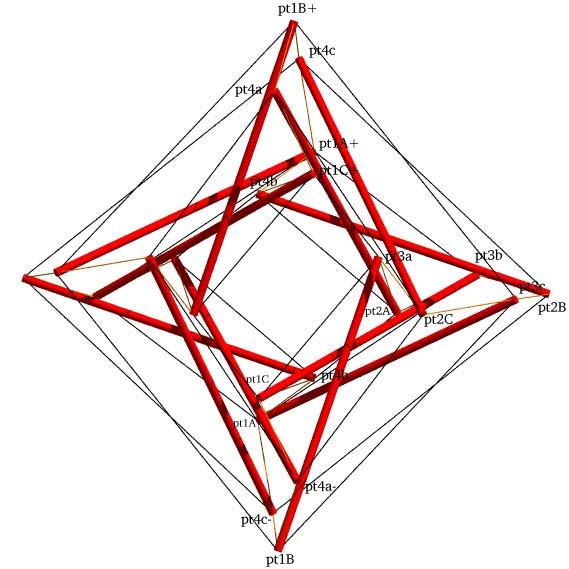

Axial View of the Four-Stage Tensegrity Torus

with Point Labels

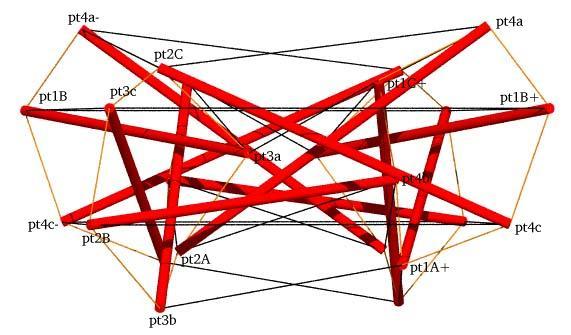

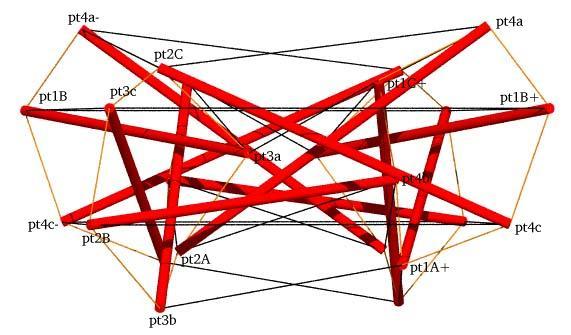

Plane View of the Four-Stage Tensegrity Torus

with Point Labels

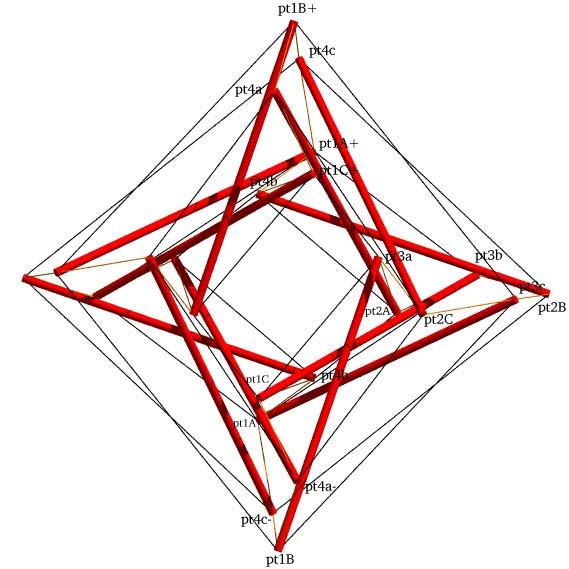

Schematic for the Tensegrity Torus

Member Descriptions

[name, end point names, weight (if in objective function),

second power of length (if a constraint), member category,

Obj/Con/Exc (put in objective function, use as a constraint or

exclude from computations), flags]

For assembly purposes, only the name and end point names are

of interest. The other information may be of interest after

A Practical Guide to Tensegrity Design has been consulted.

<Member> st13a pt1A pt3c 0.0 sqr(2.5) 1 Con CalcClear Inelastic *

<Member> st24a pt2A pt4a 0.0 sqr(2.5) 1 Con CalcClear Inelastic *

<Member> guy1a pt1A pt3b 1.00 0.0 3 Obj *

<Member> guy2a pt2A pt4b 1.00 + 0.50 0.0 7 Obj *

<Member> TS23a pt2A pt3a 0.0 sqr(0.8007685) 2 Con *

<Member> tS23a pt2A pt3b 0.0 sqr(0.8007685) 2 Con *

<Member> tT31a pt3a pt1C+ 0.60 + 0.50 0.0 3 Obj *

<Member> tT42a pt4a- pt2C 0.60 0.0 3 Obj *

<Member> TS41a pt4a pt1B+ 0.0 sqr(0.8007685) 2 Con *

<Member> tS41a pt4a pt1C+ 0.0 sqr(0.8007685) 2 Con *

<Member> st13b pt1B pt3a 0.0 sqr(2.5) 1 Con CalcClear Inelastic *

<Member> st24b pt2B pt4b 0.0 sqr(2.5) 1 Con CalcClear Inelastic *

<Member> guy1b pt1B pt3c 1.00 - 0.50 0.0 3 Obj *

<Member> guy2b pt2B pt4c 1.00 - 0.50 0.0 3 Obj *

<Member> TS23b pt2B pt3b 0.0 sqr(0.8007685) 2 Con *

<Member> tS23b pt2B pt3c 0.0 sqr(0.8007685) 2 Con *

<Member> tT31b pt3b pt1A+ 0.60 0.0 3 Obj *

<Member> tT42b pt4b- pt2A 0.60 + 0.50 0.0 7 Obj *

<Member> TS41b pt4b pt1C+ 0.0 sqr(0.8007685) 2 Con *

<Member> tS41b pt4b pt1A+ 0.0 sqr(0.8007685) 2 Con *

<Member> st13c pt1C pt3b 0.0 sqr(2.5) 1 Con CalcClear Inelastic *

<Member> st24c pt2C pt4c 0.0 sqr(2.5) 1 Con CalcClear Inelastic *

<Member> guy1c pt1C pt3a 1.00 + 0.50 0.0 3 Obj *

<Member> guy2c pt2C pt4a 1.00 0.0 3 Obj *

<Member> TS23c pt2C pt3c 0.0 sqr(0.8007685) 2 Con *

<Member> tS23c pt2C pt3a 0.0 sqr(0.8007685) 2 Con *

<Member> tT31c pt3c pt1B+ 0.60 - 0.50 0.0 3 Obj *

<Member> tT42c pt4c- pt2B 0.60 - 0.50 0.0 3 Obj *

<Member> TS41c pt4c pt1A+ 0.0 sqr(0.8007685) 2 Con *

<Member> tS41c pt4c pt1B+ 0.0 sqr(0.8007685) 2 Con *

Rotation Matrices

Only part of the structure is specified using the members

above. The rest is generated using symmetry transformations.

Here the first symmetry transformation is specified as a 3x3

pre-multiplication matrix in row-major format. As with

the members, the first item is always the label used for

the transform.

<XMat> x1 cos(2*pi/2) (-sin(2*pi/2)) 0 sin(2*pi/2) cos(2*pi/2) 0 0 0 1

In-Situ Member Lengths

These are the lengths of the members when they are in place

and prestress is applied. The strut lengths are from

screw-eye center to screw-eye center, as are the tendon lengths.

These values are in model units.

st13a: 2.5 st24a: 2.5 guy1a: 2.14766

guy2a: 1.55457 TS23a: 0.800768 tS23a: 0.800768

tT31a: 0.96985 tT42a: 1.67562 TS41a: 0.800768

tS41a: 0.800768 st13b: 2.5 st24b: 2.5

guy1b: 2.76645 guy2b: 2.76645 TS23b: 0.800769

tS23b: 0.800768 tT31b: 1.67562 tT42b: 0.96985

TS41b: 0.800768 tS41b: 0.800768 st13c: 2.5

st24c: 2.5 guy1c: 1.55457 guy2c: 2.14766

TS23c: 0.800768 tS23c: 0.800768 tT31c: 2.83827

tT42c: 2.83827 TS41c: 0.800768 tS41c: 0.800768

Relative Member Prestress Force Magnitudes

These values are useful for developing an assembly

strategy for the structure. The tighter tendons are much

easier to tie in place early on, while the looser tendons

can be left to the last. This information is also used

to adjust tendon lengths since the measured length of a tendon

will be shorter for a highly-stressed tendon with the same

in-situ length as a tendon which is not so stressed.

st13a: -2.39294 st24a: -3.86391 guy1a: 2.14766

guy2a: 2.33185 TS23a: 2.20609 tS23a: 1.64125

tT31a: 1.06684 tT42a: 1.00537 TS41a: 1.64437

tS41a: 1.64125 st13b: -3.14587 st24b: -3.14587

guy1b: 1.38323 guy2b: 1.38323 TS23b: 1.64437

tS23b: 1.57615 tT31b: 1.00537 tT42b: 1.06684

TS41b: 2.20609 tS41b: 1.31055 st13c: -3.86391

st24c: -2.39294 guy1c: 2.33185 guy2c: 2.14766

TS23c: 1.50937 tS23c: 1.31055 tT31c: 0.283827

tT42c: 0.283827 TS41c: 1.50937 tS41c: 1.57615

Average tendon force magnitude: 1.50888

Worst-Case Clearances in Model Units

These clearances are measured from member centerline to

member centerline. The labels of the two members are specified

as well as a transformation for the second member. If "id"

is specified for the transformation, it means none was applied.

0.177344 st13a tT42b id

0.143459 st24a tT31a id

0.148135 st24a st24b id

0.123907 st24a TS41b id

0.141201 st24a st13c id

0.141201 st24a st13c x1

0.143459 st24a guy1c x1

0.148135 st13b st13c id

0.143459 st13c guy2a id

0.123907 st13c TS23a id

0.143459 st13c tT42b id

0.177344 st24c tT31a id

Construction Lengths (in millimeters and halves)

The construction length of a tendon is less than the in-situ

length since when the tendon is measured off it isn't under

any prestress force. The construction length for the strut

represents the length of a 5/16-inch-diameter wooden dowel.

The tendons can be made of braided nylon fishing line.

Prestress forces were assumed not to affect strut lengths.

Elongation of Tendon of Unit Cross Section

Under Force of Average Magnitude (fraction)> .02

Length Scale Factor> 290/2.5

Strut and Tendon Hub Adjustments - s;t> 5 3.5

(The 5 mm adjustment for the strut is the amount

the screw-eye center extends from the dowel. The 3.5 mm

adjustment for the tendon is half the outer diameter of the

screw eye.)

st13a: 280 0 st24a: 280 0 guy1a: 235 1 guy2a: 168 0

TS23a: 83 1 tS23a: 84 0 tT31a: 104 0 tT42a: 185 0

TS41a: 84 0 tS41a: 84 0 st13b: 280 0 st24b: 280 0

guy1b: 308 1 guy2b: 308 1 TS23b: 84 0 tS23b: 84 0

tT31b: 185 0 tT42b: 104 0 TS41b: 83 1 tS41b: 84 1

st13c: 280 0 st24c: 280 0 guy1c: 168 0 guy2c: 235 1

TS23c: 84 0 tS23c: 84 1 tT31c: 321 0 tT42c: 321 0

TS41c: 84 0 tS41c: 84 0

Axial View of the Four-Stage Tensegrity Torus

with Point Labels

Plane View of the Four-Stage Tensegrity Torus

with Point Labels

Schematic for the Tensegrity Torus

structure file: torus/x3l04torus1.rc

variable file: torus/x3l04torus1.dat

digit list: src/mm.dls

|

CONTACT:

Bob Burkhardt

Tensegrity Solutions

Box 426164

Cambridge, MA 02142-0021

USA

e-mail: bobwb@juno.com